Supplied

SuppliedRecent findings from an experiment at the University of Alberta show that using the heating element of a three-dimensional (3D) printer can kill off harmful bacteria, making 3D-printed food safe and ready to eat for at-home consumers.

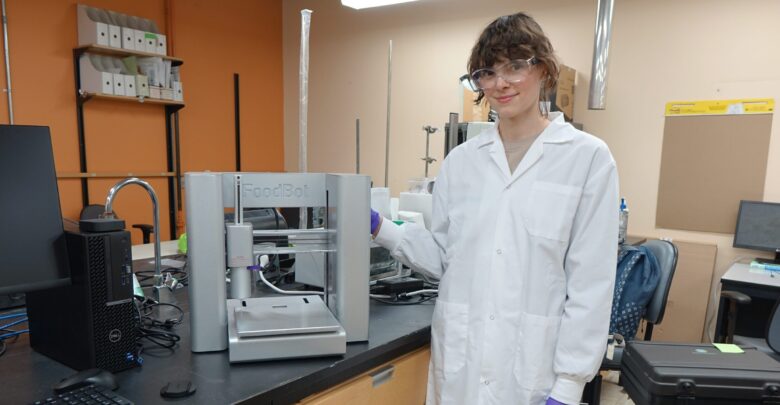

Sparked by her curiosity around sustainability, Julia Barsukova wanted to combine research in sustainability with emerging technologies and microbiology. Barsukova recently obtained a master’s degree in food science and bioresource technology. Her work in the Food Safety and Sustainability Engineering (FSSE) Research lab dives into the microbial safety of 3D-printed food.

3D printers can help reduce food waste, Barsukova says

According to Barsukova, 3D-printing food helps minimize food waste through utilizing “food products that are not usually usable or get thrown out.” Additionally, she said 3D-printing food could save time and money for the food industry.

With 3D-printing technology, “you can tailor towards any nutritional needs,” Barsukova said. It allows for the production of foods with complex shapes, flavours, textures, and various nutritional benefits. It can customize diet plans for athletes, astronauts, hospital patients, and even children by tailoring to different allergies or dietary restrictions.

“The process I work with is extrusion-based,” Barsukova said. Extrusion-based 3D-printing uses a syringe to transfer flowable food items, like pudding and mashed potatoes, through the nozzle.

The heating element, which consists of a stainless steel barrel heated by a thin plastic film, easily shapes the product. In order to design the food, you convert the design to code and insert it into the machine. The machine then follows the printing instructions.

Mathematical simulations can help ensure safety in 3D-printing tools

Barsukova’s experiment aimed to address the lack of regulation for 3D-printed foods. She stated that “whatever you print is what you eat.”

According to Barsukova, if contaminated food goes through the printer, or the syringe itself contains contaminants, there is a risk of food poisoning.

Additionally, due to the high moisture levels required for the food printing process, contamination is a risk. Barsukova said the microbial safety of 3D-printed foods has not been fully investigated.

Another issue that Barsukova highlighted is that 3D printers aren’t designed with food in mind. Certain components can’t be taken apart for cleaning, posing a risk for food safety.

For her research, Barsukova contaminated pudding with Salmonella enterica serovar Typhimurium. She heated the pudding using time-temperature combinations ranging from 10 to 40 minutes and from 55 degrees Celsius to 66 degrees Celsius. The greatest reduction in bacteria occurred when the barrel was heated for 40 minutes at temperatures of 63 and 66 degrees Celsius.

Barsukova also utilized numerical modeling. She created heat maps within the syringe to help identify cooler spots where the bacteria wasn’t reducing. She noted that mathematical simulations are useful additional tools that can help ensure safety when 3D-printing foods.

Barsukova aims to “set a guideline for the future” of 3D printing technology

Her experimental findings confirmed that bacteria present in the contaminated pudding, when put through the syringe, reduced at a higher rate when exposed to increased temperatures for longer periods.

“It’s not necessarily that this is new information. [It] has been known at which temperature bacteria gets inactivated,” Barsukova said. However, this proves that the heating element of a 3D printer is successful at inactivating the contaminant.

She compared using this technology to using appliances such as a microwave or oven. There are certain temperatures for cooking that are tested and proven to make food safe for consumption.

Through her research, Barsukova aims to “set a guideline for the future” as 3D-printing food technology progresses. Considering the technology is still in development, Barsukova said that guidelines and regulations will have to be implemented for industry applications.

“This is mostly geared towards at-home consumers right now … but obviously in the industry, they will have to implement bigger procedures [and] bigger guidelines,” Barsukova said.