Supplied

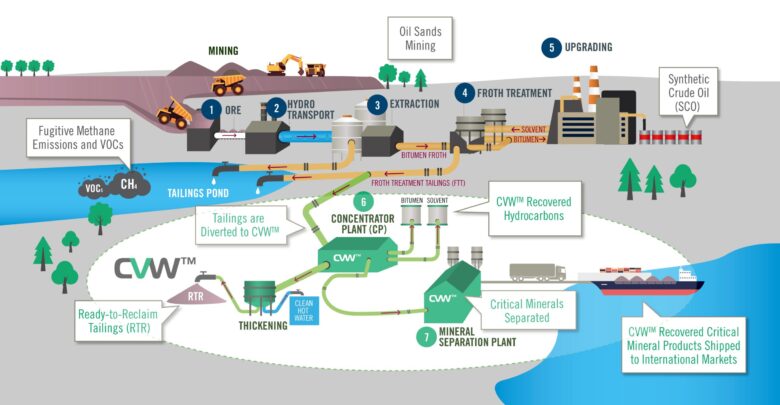

SuppliedThe University of Alberta has partnered with CVW CleanTech to conduct a three-year, $1.4 million research project focused on optimizing the recovery of rare earth elements from oil sands waste.

Rare minerals such as zircon, titanium, and monazite are used in the creation of clean technologies, according to Kevin Moran, executive vice-president and chief technology officer of CVW Cleantech. The clean technologies these rare minerals support are essential to decarbonizing the economy, Moran said.

Decarbonization is a process that aims to reduce or eliminate carbon dioxide emissions from or in an environment. Both the Government of Alberta and Government of Canada have set the intention to work towards decarbonization.

“Those critical minerals are critical for a reason. They’re critical to Alberta and Canada because they support the transition to decarbonize our economy. They are a critical component to many of the technologies that will allow us to transition towards decarbonization,” Moran said.

One form of oil sands waste are tailing streams — waste fluids from the oil sands extraction process. Through reprocessing the tailing streams, they can extract valuable materials that were previously missed.

“It is an important form of recycling that I really view as an essential component of the responsible development of the oil sand resource that is owned by the province. It’s in the public interest,” Moran said.

“[With] the recovery of monazite alone, we can contribute over half a per cent to Alberta’s GDP,” Moran says

A benefit of recovering rare earth minerals from oil sands tailings is that they are already liberated, Qi Liu said. Liu is a professor in the department of chemical and materials engineering at the U of A. He is also one of five principal investigators (PIs) for this research project.

“[When] you get the mineral from a harder rock wall, you actually have to crush and grind all of those rocks into fine particles to liberate the minerals. In oil sands, they are already liberated so that saves a lot of energy. It really is an upside,” Liu said.

Of the rare minerals, monazite is especially valuable, Moran said. If the researchers are able to successfully recover monazite from oil sands waste there is a significant economic benefit to Alberta, Moran said.

“[With] the recovery of monazite alone, we can contribute over half a per cent to Alberta’s GDP,” Moran said.

“There are always going to be applications for these kinds of materials,” Liu says

In addition to optimizing the recovery of critical minerals, the researchers also intend to investigate advanced manufacturing opportunities to utilize the critical minerals, Moran said.

According to Liu, one goal is the creation of high entropy alloys from the critical minerals. High entropy alloys are “a really valuable high-tech product that is mainly used for high temperature processes,” Liu said.

“They are [used] in nuclear reactors and some wind turbines. [They are useful] especially in the oil and gas industry because they need material that is corrosion resistant. There are always going to be applications for these kinds of materials,” Liu said.

From the U of A’s perspective, this project is an opportunity to train highly qualified personnel, Liu said.

“[When] these people have graduated [with] the skills they gained, they will actually go out and work for the industry. They will definitely contribute to the economy.”